Technology

Synthetic Rutile

Process

(Green RutileTM)

The Green Rutile Process

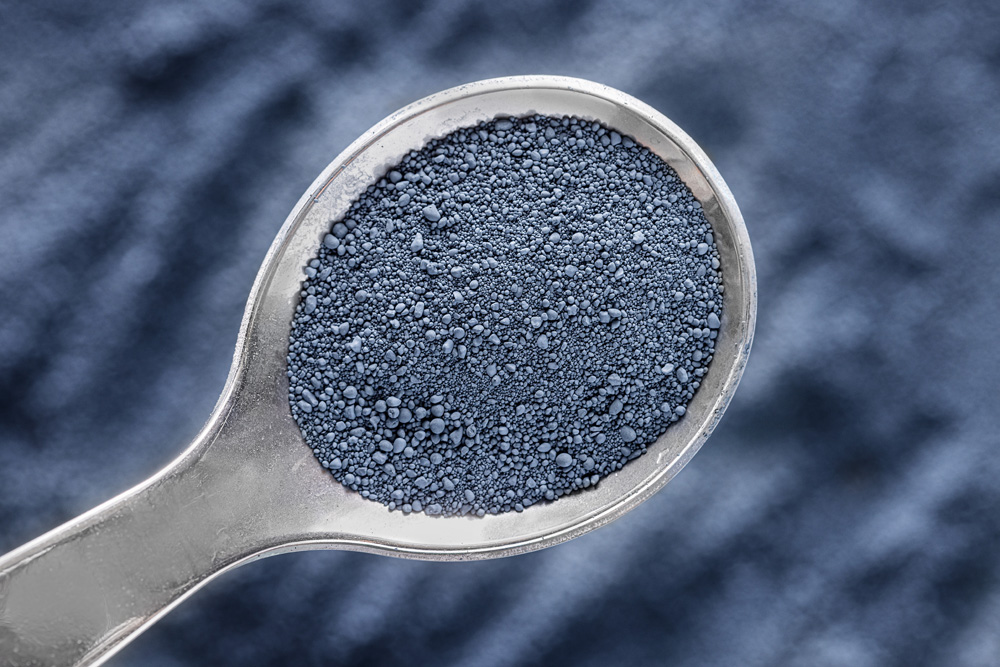

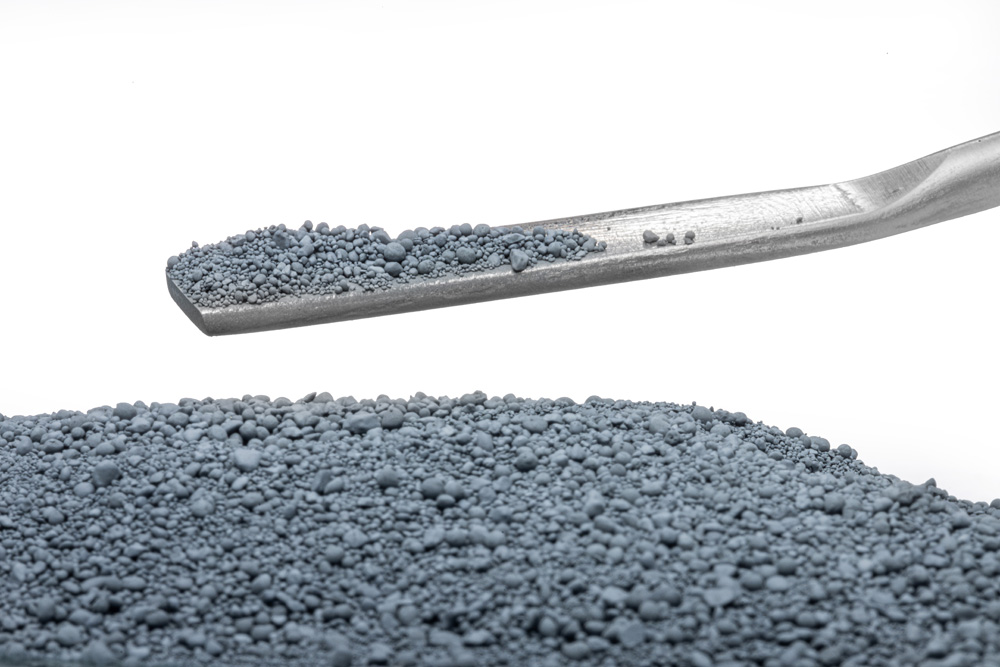

IperionX’s Green Rutile process starts with the milling of ilmenite, including ilmenite sourced from the Company’s Titan Project. The milled ilmenite is agglomerated with a binding agent into ilmenite spheres, which are sintered and reduced with hydrogen in an electric furnace. The sintered and reduced hydrogen spheres are crushed and leached in the presence of hydrochloric acid to produce a synthetic rutile product plus an iron oxide co-product for potential sales into lithium iron phosphate battery applications.

As part of the production process, IperionX has developed a titanium recovery method with the addition of a primary reagent recovery process, including the generation of the purified iron powder co-product. This recovery process provides the potential for a substantial operating cost reduction over what would normally be realized.

Co-products of IperionX’s Green Rutile process also results in a purified iron powder for potential sales into lithium iron phosphate battery applications.