Operations

Low-carbon, Sustainable Critical Materials for America

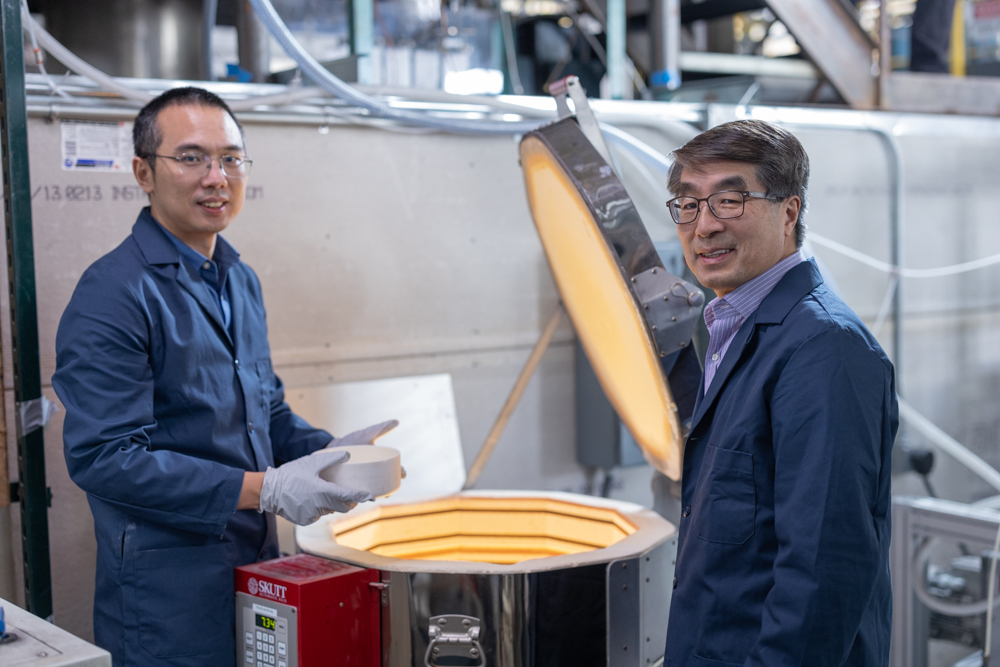

IperionX aims to be the leading developer of sustainable critical mineral and critical material supply chains in the United States.

We are working to commercialize a series of patented titanium manufacturing technologies that have the potential to significantly reduce both the cost and carbon emissions of titanium production relative to what is commercially available today. With these technologies we plan to enable a much wider uptake of titanium, with the potential to displace metals like steel and aluminum which have lower strength-to-weight ratios, inferior corrosion resistance and higher net-carbon emissions.

Further, IperionX controls one of the largest sources of titanium, zircon and rare earth elements in North America at our Titan Project in West Tennessee. Development of the Titan Project is a key component in re-shoring the titanium and critical material supply chains in North America.

Together, our ground-breaking metal technologies and our large critical mineral deposit form the core platform of our business from which we aim to re-shore critical material supply chains to the United States.

Business Operations

Metals

Our breakthrough metal processing technologies provide a pathway to closed-loop, low-carbon, titanium metal in the U.S. The technologies also have the potential to be applied to other critical minerals like zirconium and rare earth elements.

Minerals Extraction

Our 100% owned Titan Project in West Tennessee is a large-scale heavy mineral sand deposit hosting 17 of the 50 minerals as defined by the U.S. government as critical minerals. The Titan Project provides the potential to re-shore a number of highly important material supply chains to the U.S.